Have you ever wondered how your car produces such powerful lights? How can a brilliant flashlight light up hundreds of feet ahead for hours? How does it work? What mechanism drives it?

Simply put, it’s all thanks to the intricate assembly of your headlights, or more precisely, the parts: bulbs, lenses, housings, and motors. These essential components generate and orient the blinding lights, playing a crucial role in safe and illuminated nighttime driving experiences. Thanks to the precise beam, we can cruise down any road at any time of the day, regardless of the visibility.

The beam is the result of engineering and thoughtful design. In this comprehensive guide, we’ll break down the various components that make up a headlight assembly. We’ll uncover the primary parts of a headlight and its role in producing the lights that have made nighttime driving safer. Buckle up, and let’s explore the inner workings of these illuminating marvels!

Headlight Assembly

Definition and Importance

A headlight assembly, commonly referred to as a headlamp or simply a headlight, is an essential component of a vehicle. It’s mounted at the front to illuminate the road ahead. These lights are critical for ensuring that the driver can see the path clearly, especially during nighttime or in low-visibility conditions such as fog, rain, or snow.

The headlamp is the actual device attached to the car, while the headlight refers to the beam of light it produces. This distinction is important, as the headlight’s effectiveness is directly related to its design and functionality.

The importance of headlights extends beyond just providing light; they are a key safety feature of any vehicle. Here’s why they are crucial:

- Illumination: Headlights illuminate the road ahead, allowing drivers to see obstacles, pedestrians, and other vehicles in the dark.

- Visibility to Others: They ensure your vehicle is visible to other drivers, reducing the risk of collisions.

- Navigation: Headlights assist in navigating through curves, dips, and uneven terrains by highlighting the path.

- Signaling: Headlights, especially high beams and fog lights, are used to signal other drivers of your presence or to communicate during adverse conditions.

Without adequately functioning headlights, driving at night or in poor weather conditions would be incredibly dangerous. They are designed to provide the right amount of light at the right angle to ensure both the driver and other road users remain safe. Ensuring that your headlights are well-maintained and properly aligned is crucial for safe driving.

Components of a Headlight Assembly

Headlamps are essential parts of a vehicle’s lighting system and are composed of several vital components that work together to provide adequate illumination. Here’s a simple breakdown of each component and its function:

Lightbulb: The lightbulb is the light source in a headlamp. It produces a beam of light that illuminates the road. Different types of bulbs, such as halogen, LED, or HID headlights, affect the brightness and color of the light.

Electric Wires: These wires carry electrical current from the vehicle’s power source to the lightbulb, ensuring that the bulb receives the necessary power to produce light. In advanced vehicles, wires carry electric current to motors, sensors, moving panels, etc.

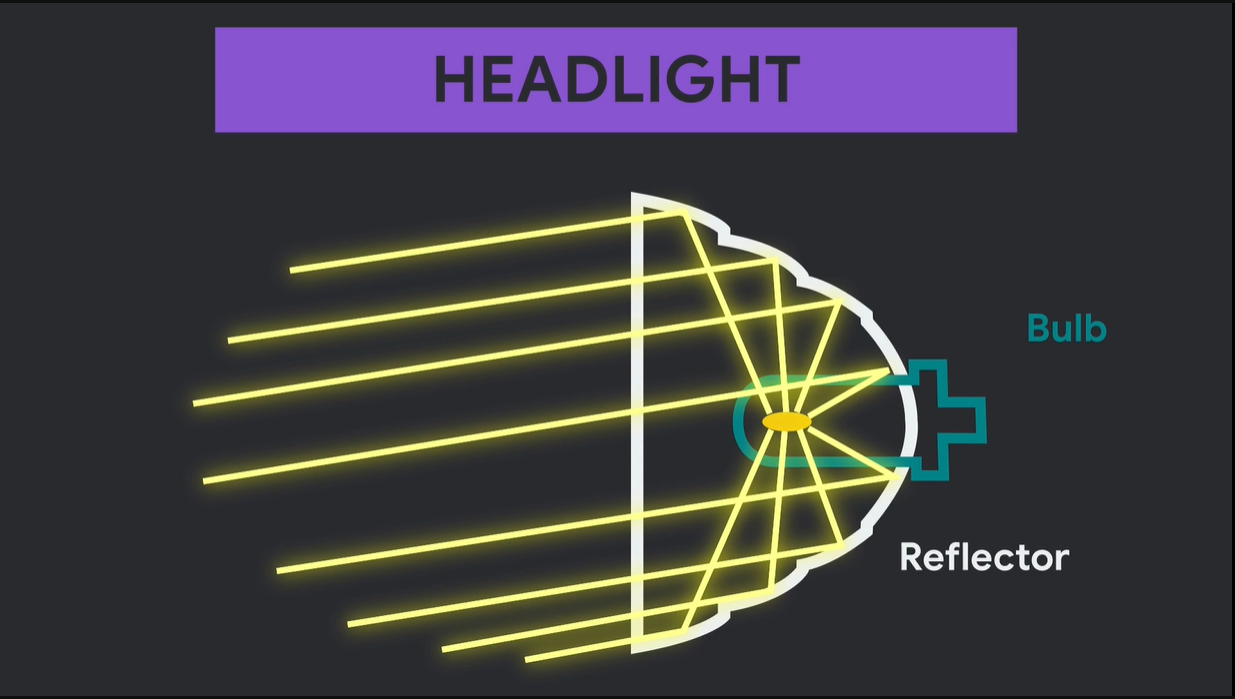

Reflective Glass: The reflective glass, often found inside the headlamp assembly, helps direct and focus the light from the bulb into a specific beam pattern. It concentrates scattered light rays from the headlight bulb and orients them in one direction.

Shielding Glass or Plastic Cover Lenses: This is the outer layer of the headlamp. It protects the internal components from dust, debris, and weather elements. The shielding surface also helps to ensure that the light beam is projected correctly and does not scatter unnecessarily.

Headlight Housing

Types of Headlight Housing

Reflector Housing:

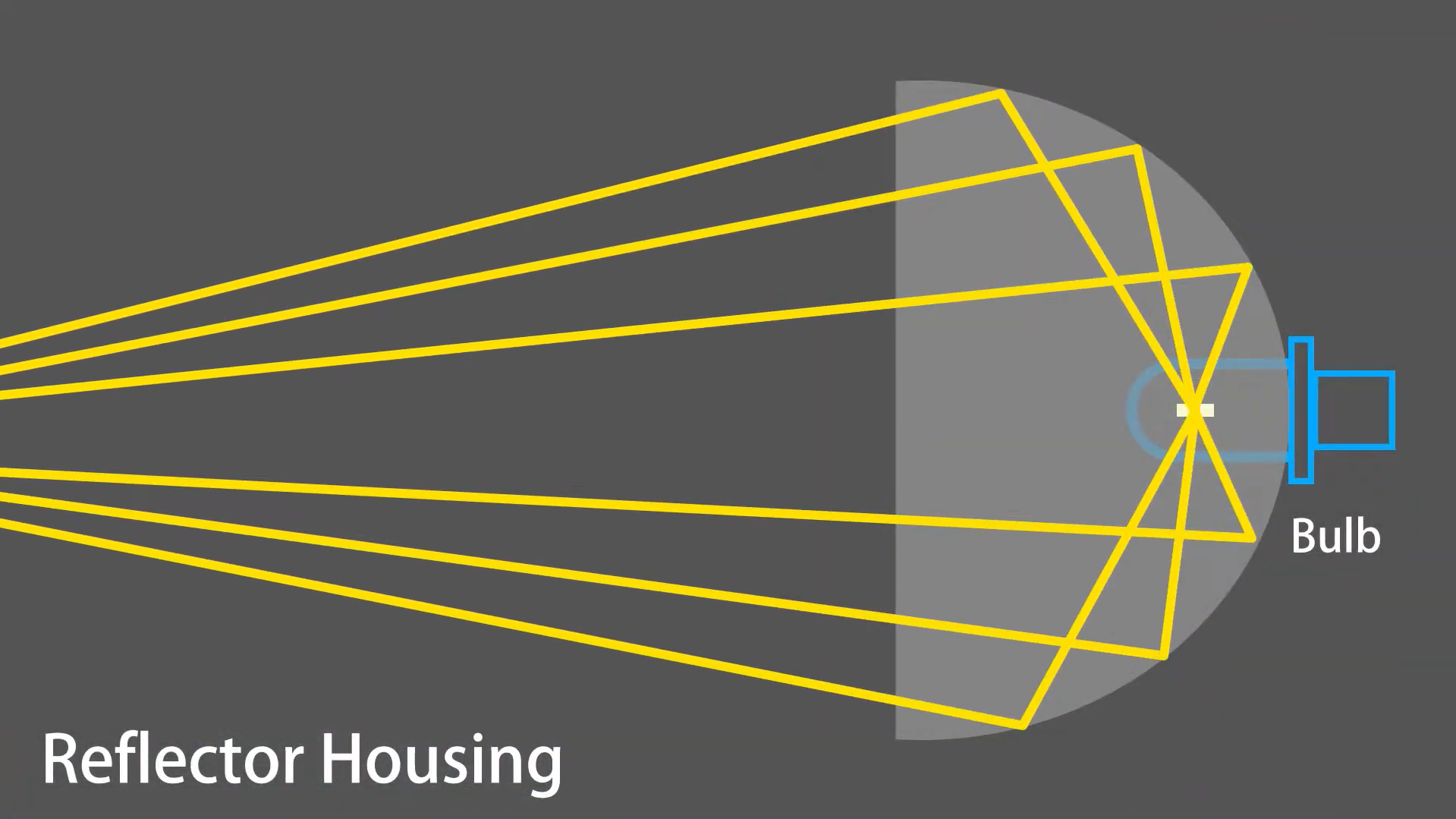

Before 1985, the standard design for vehicle headlights was a reflector housing. This housing consists of a reflective surface positioned behind the bulb, known as the reflector. The reflector directs and distributes light.

Functionality: The reflector ensures that the light emitted by the bulb is evenly spread across the road. A regular bulb shoots rays in omnidirection, which means the bulb lights up everything around it, but the brightness remains unsatisfactory.

By bouncing light off its curved surface, the reflector creates a focused beam that is brighter and far more practical than the bulb itself. This design was adequate for its time, providing a reliable way to light up the road. However, it has since been largely replaced by more advanced headlight technologies.

- Advantages:

- Simplicity and cost-effectiveness.

- Wide coverage area.

- Limitations:

- Less precise light control compared to the projector housing.

- May cause glare for oncoming drivers.

- Common Applications: Older vehicles and budget-friendly models.

Projector Housing:

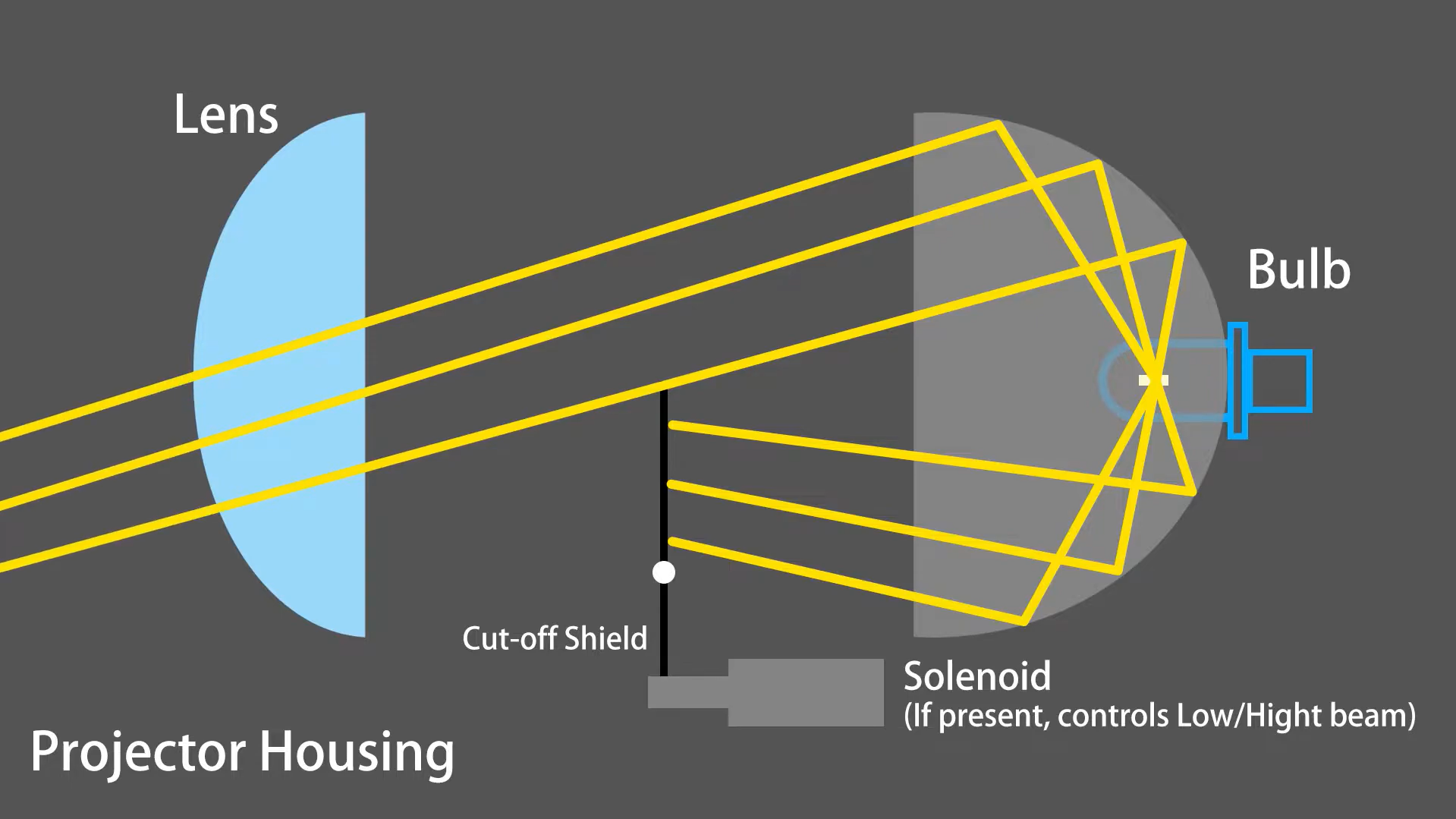

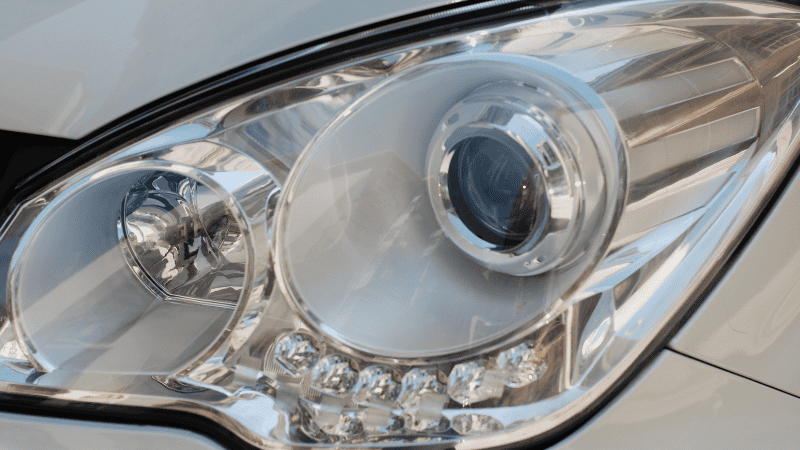

Projector housing, introduced in the 1980s, has become the standard in newer cars. This design employs a dedicated cover lens system known as the projector to create a sharp, well-defined beam of light.

Functionality: The projector lens focuses the light emitted by the bulb, resulting in a more controlled and precise beam pattern compared to earlier reflector designs.

This enhanced control improves visibility and reduces glare for oncoming drivers. Light concentration by the inner lens is more efficient than that of a reflector. Projector headlights offer superior light distribution and illuminate more effectively, which enhances overall driving safety and performance.

- Advantages:

- Precise light output with minimal scatter.

- Reduced glare for other drivers.

- Enhanced aesthetics.

- Limitations:

- Slightly higher cost.

- Common Applications: Newer cars, luxury vehicles, and performance models.

Material Selection for Headlight Housing

The headlight housing holds the bulbs securely within the vehicle’s body while shielding them from external elements. Materials for headlight housings vary based on their functional and aesthetic requirements.

Materials Used:

- Plastic (Polycarbonate): This material is commonly used due to its lightweight and impact-resistant properties. It’s cost-effective and can be molded into complex shapes, making it a popular choice for modern headlight designs.

- Glass: Although traditional and known for its clarity, glass is less common today because it is heavier and more fragile compared to plastic alternatives.

- Composite Materials: High-end vehicles often use composite materials such as carbon fiber-reinforced polymers. They help make the headlight assemblies lightweight and durable.

Design Considerations:

- Aesthetics: While clear lenses are standard, some designs incorporate textured or patterned lenses to enhance visual appeal.

- Sealing: Effective sealing is essential to prevent moisture and dust from entering the housing, which can affect headlight performance.

- Alignment Adjustments: Many headlight housings include provisions for minor alignment adjustments at the back, allowing for precise headlight alignment to ensure optimal illumination.

Headlight Bulbs

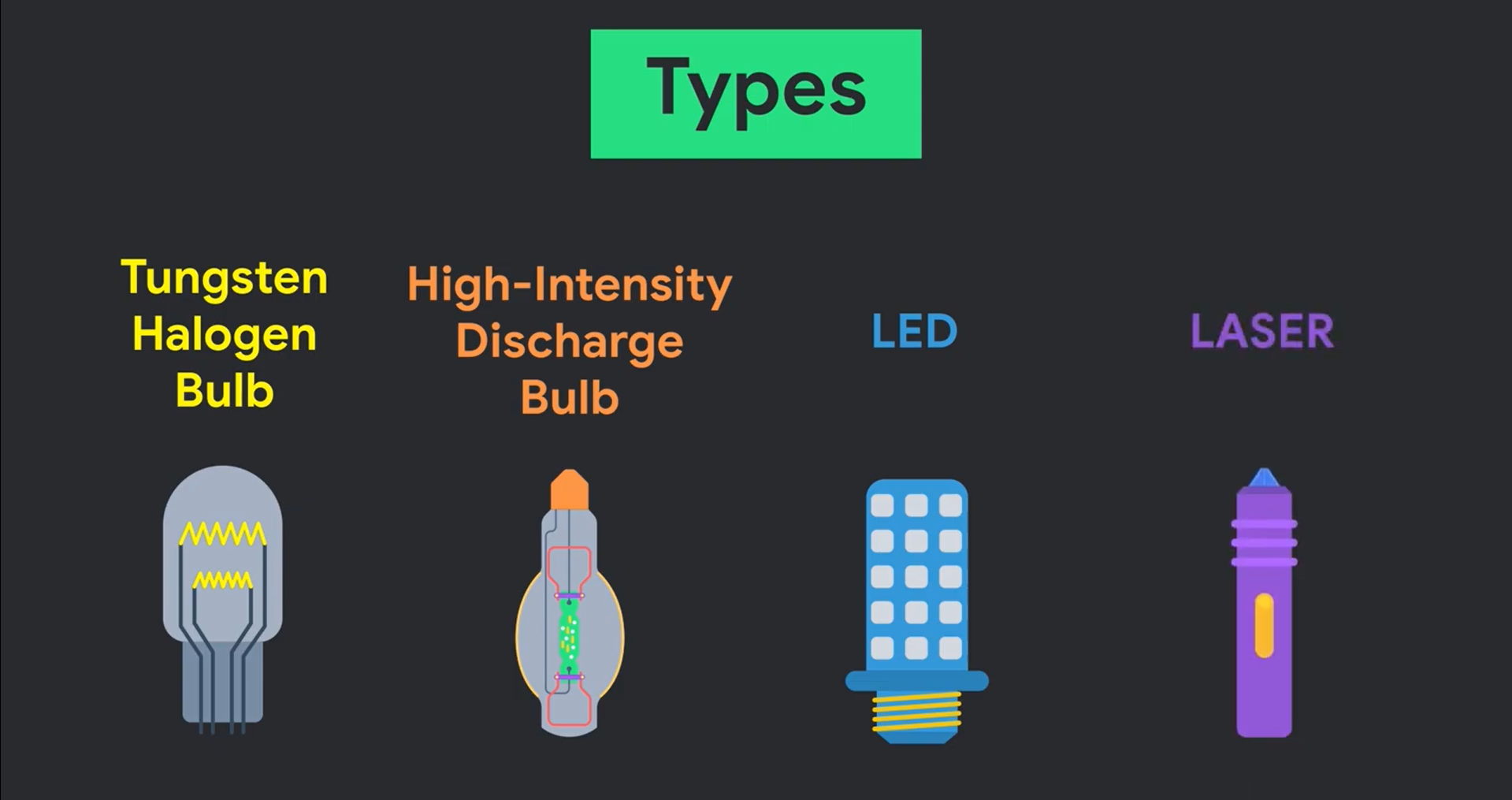

Headlamps are the core of a headlight system. The following headlamp systems are the most popular and widely used.

Types of Headlight Bulbs

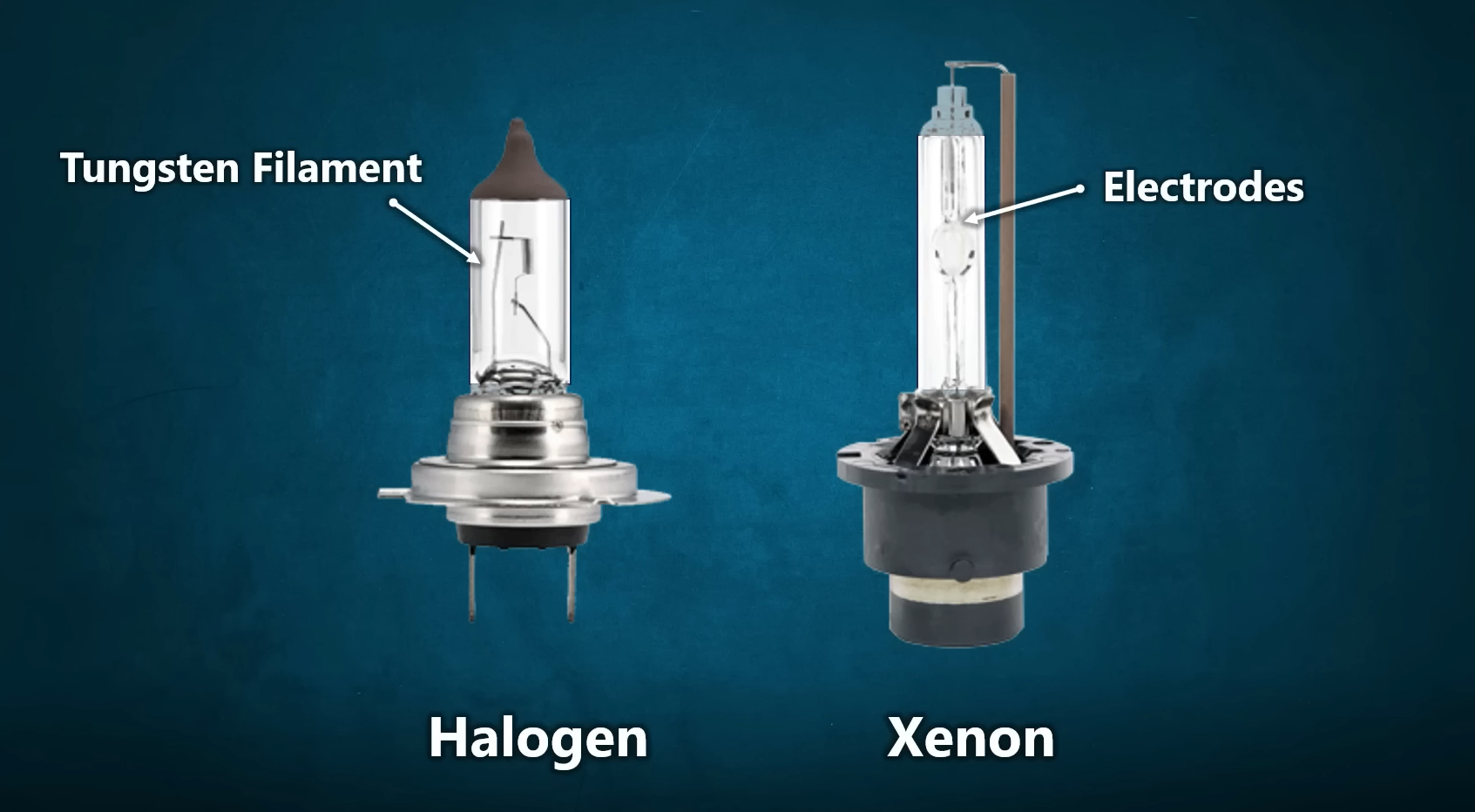

Halogen Headlights use a tungsten filament enclosed in a glass capsule filled with halogen gas to increase efficiency and lifespan. An electric current passes through the material and heats it, eventually resulting in warm, yellowish light. These bulbs typically last between 500 and 1,000 hours and have a Kelvin rating of around 3,200K to 3,500 K. The light output is about 700 to 1,200 lumens, depending on the specific bulb type.

HID Bulbs (High-Intensity Discharge) generate light by creating an electric arc between two electrodes within a chamber filled with xenon gas. This method results in much brighter light compared to halogen bulbs, which have a lifespan of 2,000 to 3,000 hours. HID headlights offer a brighter, bluish-white light with a Kelvin range typically between 4,300K and 6,000K and produce between 3,000 and 5,000 lumens for superior illumination.

LED (Light Emitting Diode) Headlights use a semiconductor that emits light when an electric current passes through it. They are highly efficient, producing very little heat, and have the longest lifespan of up to 30,000 to 50,000 hours. LED headlights generally produce a bright white light with a Kelvin range of 5,000K to 6,500K and offer around 2,000 to 4,000 lumens, providing excellent visibility with lower energy consumption.

If you’re an enthusiast, you might as well keep an eye out for Laser Headlights. They’re still relatively new technology but promise superior performance and efficiency to other bulbs.

| Feature | Halogen Bulbs | HID (High-Intensity Discharge) Bulbs | LED (Light Emitting Diode) Headlights |

|---|

Importance of Proper Headlight Bulb Maintenance

Regular inspection and maintenance of headlight bulbs are essential for ensuring safe driving conditions. By routinely checking your headlights, you can prevent flickering high beams, dead turn signal bulbs, and faulty brake lights. Proper upkeep of your car’s headlights not only ensures that your vehicle remains visible to others but also keeps you safe from potential dangers.

Headlight Lens

Material Selection for Cover Lenses

Headlight cover lenses come in two primary materials: glass and plastic, each with distinct characteristics and applications.

The glass was traditionally used as a headlight cover lens material. It has exceptional optical clarity and resistance to scratches. Glass lenses offer a streak-free, bubble-free surface, providing excellent transparency.

However, they have notable limitations, including being heavy and prone to shattering upon impact, which makes them less durable and more challenging to handle. These lenses were commonly found in older headlamp systems. Glass lenses show more dispersion optics than plastic lenses.

Nowadays, modern headlight cover lenses are mainly made of plastic, specifically polycarbonate (PC). Polycarbonate has become the material of choice for modern headlight assemblies. It is highly impact-resistant and ideal for automotive use. It is also much lighter than glass, reducing the overall weight of the vehicle.

Additionally, plastic lenses allow for smaller production tolerances that lead to more precise manufacturing. In modern vehicles, polycarbonate lenses are often used in various applications, such as inner lenses for low and high beams (bi-xenon) and fog lights. These clear cover lenses, without optical elements, primarily protect the lights from soiling and harsh weather conditions.

Importance of Headlight Lens Clarity

Clear headlight lenses ensure proper illumination and safe driving. Over time, lenses can become cloudy or hazy due to UV exposure and environmental factors such as dust, rain, fog, etc. A hazy lens reduces light output and visibility. Sometimes, it may appear that your car headlight bulb is not working correctly or getting dimmer, but it may actually be because of the lens.

The foggy lens also impairs the driver’s ability to see the road and makes the vehicle less visible to others, increasing the risk of accidents. Consider wiping the lens with a dry cloth from time to time.

Reflector and Projection Modules

Material for Reflectors

Reflectors in headlights are typically made from thermoplastics due to their precise mold reproducibility. Materials like polycarbonate (PC) and acrylic (PMMA) are common. PC is favored for its impact resistance, optical clarity, lightweight nature, and ability to withstand high temperatures, making it ideal for automotive lighting.

PMMA, on the other hand, is known for its high optical clarity and UV resistance, which are suitable for applications where light transmission and aesthetics are prioritized. In high thermal stress situations, aluminum or magnesium may be used. Silicone is utilized in advanced LED systems for its flexibility and extreme temperature resistance.

Function and Importance of Projection Modules

Projection modules in today’s headlamps help car owners achieve precise beam patterns with high luminous flux collected. These modules allow for more focused light distribution, reducing glare for oncoming traffic while illuminating the road ahead more effectively.

Their versatility supports a wide range of headlamp designs. Using them, manufacturers can implement advanced lighting technologies, such as adaptive headlights and LED systems, tailored to specific driving conditions and vehicle aesthetics.

Turn Signal and Other Components

Function and Importance of Turn Signal Bulb

Turn signal bulbs are necessary for signaling lane changes and turns as they help ensure communication with other car drivers. A headlight assembly also includes the reflector, which directs light; the housing, which protects internal components; and mounting brackets, which secure the assembly to the vehicle. Each component plays a vital role in headlight functionality and vehicle safety.

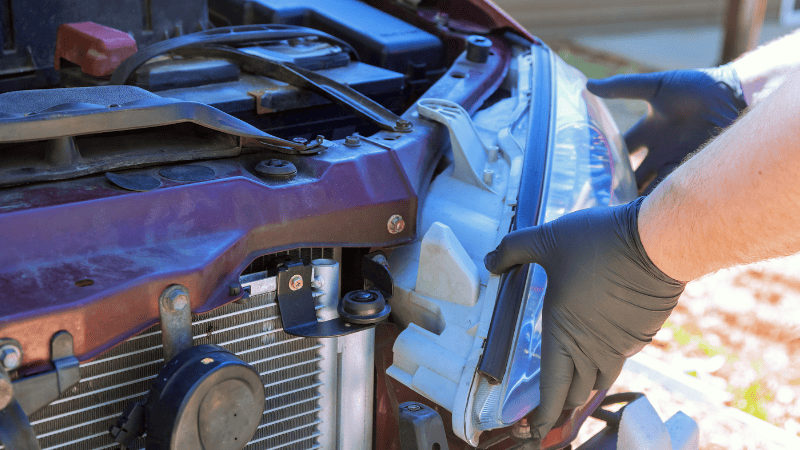

Headlight Assembly Replacement

Cost Estimation and Process

The cost to replace a headlight assembly ranges from $250 to $700, with some shops charging up to $800 per assembly. The total cost depends on which components are damaged or faulty. Labour costs are typically included if an auto repair performs the replacement. Depending on the build and price of the headlight bulb, the headlight reflector, and other components, the overall headlight assembly replacement cost can fluctuate.

DIY vs. Professional Replacement

A DIYer with appropriate knowledge and tools can replace automotive lighting. However, changing a headlight bulb is more complex due to the involvement of additional components like the reflector, housing, and mounting brackets. Professional replacement ensures proper installation and alignment, minimizing the risk of errors and potential safety issues.

Choosing the Right Headlight Assembly

Vehicle Compatibility and OE vs. Aftermarket

When replacing a headlight assembly, check your vehicle’s year, make, and model to ensure compatibility. Both OE (Original Equipment) and premium aftermarket parts offer equivalent quality, fitment, and functionality.

When comparing OE (Original Equipment) and aftermarket parts, consider the following details:

- Quality: OE parts are typically manufactured to the vehicle manufacturer’s specifications, while aftermarket parts can vary in quality.

- Fitment: OE parts are designed for perfect fitment. Aftermarket parts may require adjustments.

- Warranty: OE parts usually come with a warranty from the vehicle manufacturer, whereas aftermarket parts may have varying warranty terms.

- Price: OE parts are often more expensive, while aftermarket parts can be more cost-effective but vary widely in price.

- Performance: OE parts match the vehicle’s original performance standards, while aftermarket parts may offer different performance characteristics.

- Brand Reputation: OE parts are from the vehicle’s original manufacturer, while aftermarket parts come from various manufacturers with differing reputations.

Conclusion

A headlight assembly is the most substantial part of a vehicle’s lighting system. Replacing it can improve visibility on dark roads and protect other connected components. A DIY replacement effort can save you some money on labor costs. But if you’re driving an advanced vehicle, plug-and-play is not always streamlined.

Consider hiring an expert or reaching out to professional platforms such as Carlightvision. Our professionals are dedicated to solving headlight issues with maximum guarantee.

Carlightvision: Your Trusted Supplier for OEM-Compatible Headlight Assemblies

Proper headlight maintenance is essential for safe driving. Headlamps focus light onto the road using specific lighting technologies. Understanding the structure and technology of headlamps helps maintain their effectiveness. Regular maintenance ensures optimal performance, prevents accidents, and provides clear visibility in various driving conditions. Contact us today to get the best price!