When replacing or upgrading tail lights, deciding whether to invest in OEM tail lights or aftermarket options is a crucial decision. The right choice is not just about upfront cost. It impacts fitment, electronic compatibility, durability, and cost over time.

In this guide, we’ll compare OEM and aftermarket options. Reveal hidden risks to help you make the right purchase for your vehicle or fleet.

Tail Light vs Brake Light: Clear Definitions

Confused about whether tail lights and brake lights are the same? Before deciding on OEM and aftermarket options, it’s important to understand the difference between tail lights and brake lights. Confusing the two can lead to improper replacements or unexpected errors.

Tail lights are always illuminated when the headlights are on. They provide general visibility to help other drivers see your vehicle in low-light conditions. Brake lights activate only when you press the brake pedal. Brake lights signal to other drivers behind you that you are slowing down or stopping.

Many tail light assemblies house multiple components, including tail lights, brake lights, reverse lights, and turn signals. Some models use the same bulb for brake and tail functions.

OEM Tail Light Assemblies: What You’re Paying For

OEM tail lights are manufactured by the original vehicle maker. They are designed for perfect fitment and tested to meet strict quality standards.

Advantages of OEM Tail Lights:

- Exact Fit: The original manufacturer did vehicle-specific tooling so that every component matches your car perfectly.

- Reliable Electronics: OEM assemblies match your car’s electrical system without any error codes or dashboard warnings.

- Quality Assurance: OEM tail lightsaretested for quality performance. They are durable and water-resistant.

- Regulatory Compliance: OEM parts are fully compliant with DOT and E-Mark regulations.

- Longer Lifespan: Strict quality assurance provides peace of mind with low failure risks that last longer.

Drawbacks:

- Higher Cost: OEM parts generally carry a premium upfront cost.

- Limitations: OEM parts are offered only in the designs approved by the vehicle manufacturer, which limits styling options. In addition, they are typically sold through authorized dealers only. It results in higher prices and longer delivery times.

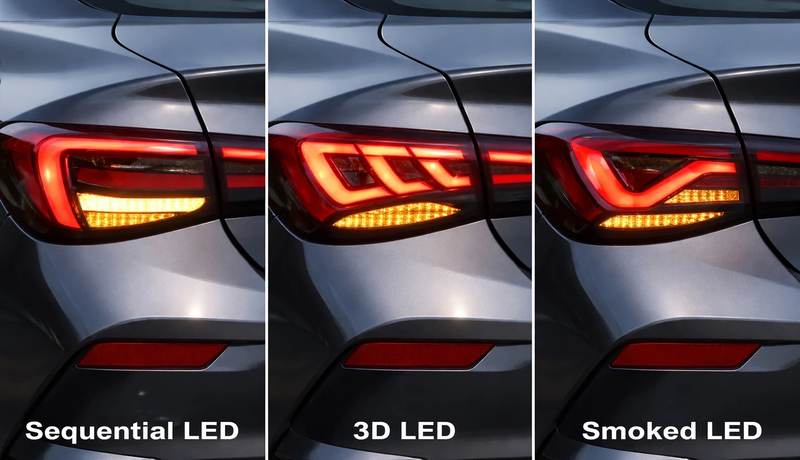

Aftermarket Tail Lights: Why Quality Varies

Aftermarket taillights are produced by third-party manufacturers. That’s why quality can vary widely depending on testing, design, and manufacturing standards.

Some aftermarket tail lights fail because of:

- Shared Molds: Some manufacturers use one mold for multiple vehicle models. Even small shape differences can cause poor fitment, gaps, or stress during installation.

- Lower-quality materials: Cheaper plastics, thinner housings, and lower-grade seals can crack, fade, or leak over time.

- Loose manufacturing tolerances: Some manufacturers do not strictly control dimensions. As a result, parts cannot align properly, seal evenly, and mount securely.

These shortcuts reduce cost, but they also increase the risk of fitment issues, water ingress, fogging, and early failure.

But not all aftermarket taillights are bad. Many reputable manufacturers invest in vehicle-specific designs, higher-grade materials, and proper testing. They produce quality parts that can perform very close to OEM. Sometimes, at a lower price if you choose carefully.

Quality Tiers in Aftermarket:

- Budget Aftermarket: Cheapest options with the highest risk of failure or water ingress.

- Mid-Tier Aftermarket: Balance of cost and reliability. Mostly CANBUS-compatible.

- OEM Equivalent Aftermarket: High-quality reproductions. More expensive but mostly matches the factory taillights’ performance.

Why Some Aftermarket Tail Lights Fail, and Others Don’t

Aftermarket tail lights problems start from engineering precision, manufacturing methods, and quality control, not just brand name or price. The most common failures can be traced to two technical areas: fitment accuracy and sealing integrity.

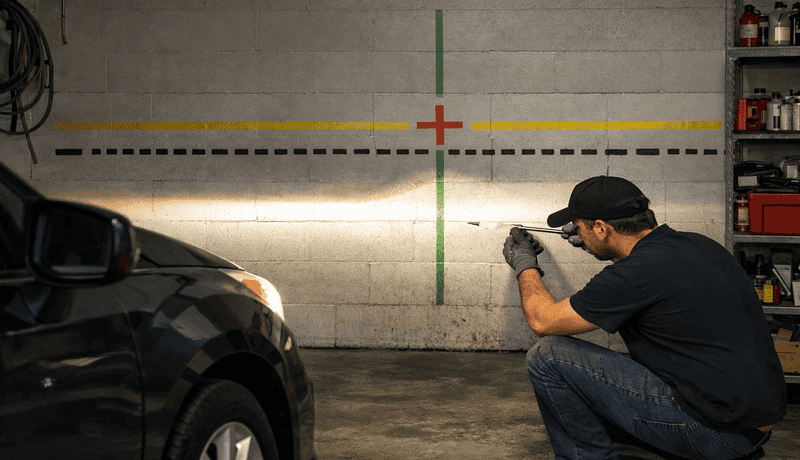

1. Fitment Differences: Where the Problems Come From

OEM parts are designed using the vehicle manufacturer’s original CAD dataand body panel tolerances. They are produced with vehicle-specific injection molds. That’s why mounting points, housing edges, and gasket channels align precisely with the car’s rear body structure.

In contrast, aftermarket manufacturers, especially at the low-cost end, do not have access to original OEM CAD files. So they:

- Reverse engineer parts from physical samples.

- Use shared or semi-universal molds for multiple vehicle models.

- Allow wider dimensional tolerances during production.

For instance, a small deviation, even 1-2 millimeters, results in:

- uneven gaps between the taillights and the body panel.

- Mounting tabs that require force or bending to install.

- Stress on the housing or lens during tightening can cause cracks over time.

This is why some aftermarket tail lights physically “fit” but feel tight, misaligned, or difficult to install.

2. Sealing Failures: The Most Common Issue

OEM tail light assemblies use vehicle-specific gasket profiles. They are designed to match the exact contour of the car body. These seals are engineered to apply uniform compression pressure when the light is installed and create a watertight barrier.

Lower quality aftermarket fails because:

- Gasket materials are thinner or lower-grade rubber that loses elasticity over time.

- Gasket shapes are generic, not body-specific.

- Contact surfaces on the housing are uneven due to lower mold precision.

This results in seals that do not compress evenly. Over time, this leads to condensation or fogging inside the lens. The uneven contact surfaces cause water pooling at the bottom of the housing. Good lighting reduces the risk of rear-end collisions.

Moisture and oxygen enter the assembly through poor seals, and water acts as an electrolyte. This creates oxidation on metal contacts and leads to corrosion of connectors, LED boards, and wiring. Moisture bridging circuits and increasing contact resistance can cause short-circuits and flickering lights.

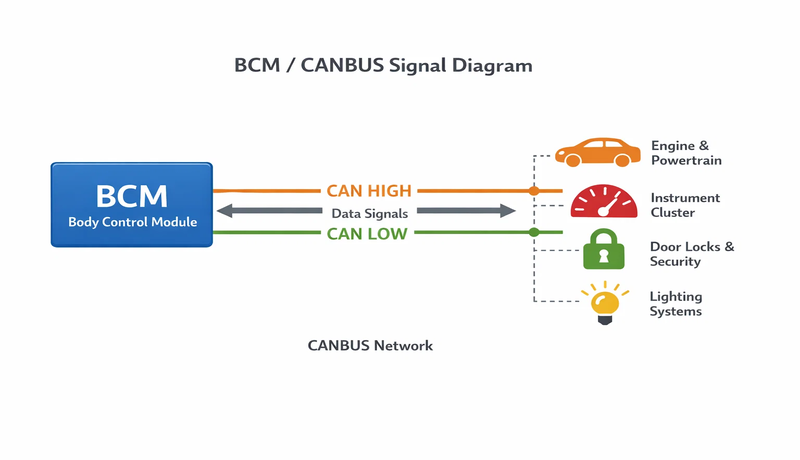

Why Aftermarket LED Tail Lights Cause Error Codes and How to Avoid Them

Most of the time, aftermarket LED taillights trigger dashboard warnings. It is because modern vehicles actively monitor the electrical behavior of each lighting circuit. When that behavior falls outside expected parameters, the system flags it as a fault even if the light appears to work normally.

Why Error Codes Happen

Modern vehicles use a Body Control Module(BCM) to check each bulb’s functionality. CANBUS system responds to load changes. It measures current draw and circuit resistance.

Traditional bulbs like halogen and incandescent bulbs draw a known, relatively high current. LED light bulbs consume far less power than old bulbs. When the BCM detects less power than the expected load, it assumes that the bulb is missing or burned out. As a result, it can trigger the dashboard dialog warning.

In some vehicles, the BCM also sends short diagnostic pulses through the circuit. Traditional bulbs or low-quality LED drivers can misinterpret these pulses, causing flickering or fault signals.

Why OEM LED Tail Lights Don’t Trigger Errors

OEM LED tail lights are engineered with internal drivers that match the electrical load profile expected by the BCM. They are validated during vehicle development for safety. It helps the control module to recognize them as normal and functioning lights, so no ABS or other warnings are generated.

How Aftermarket LED Tail Lights Can Avoid Errors

High-quality aftermarket LED assemblies avoid faults by:

- Using CANBUS-compatible driver circuits that simulate the electrical behavior of halogen bulbs.

- Integrating proper load resistors or electronic load simulation inside the housing instead of external add-ons.

- Filtering diagnostic pulses so they don’t interfere with LED operation.

External resistors generate heat and can damage plastic housings or nearby wiring if mounted incorrectly. Poor wiring connections create resistance, voltage drops, or intermittent faults that trigger warnings even if the light works.

Different vehicle models and brands use different BCM logic and tolerance thresholds. Some vehicles are very tolerant of LED lights, and some are extremely sensitive. They can trigger warnings unless the electrical load matches OEM specifications very closely.

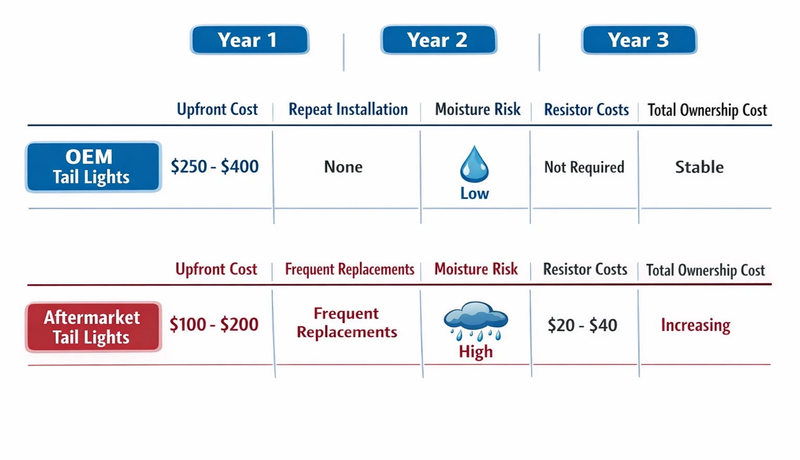

The True Cost of OEM vs Aftermarket Tail Lights Over Time

Looking only at the purchase can be misleading. The real cost difference between OEM and aftermarket tail lights becomes visible after months or years of use.

OEM costs are more predictable because they are specifically designed for the vehicle. Most factory taillights fit the first time correctly. They do not trigger electrical faults and maintain sealing over long periods. This means the initial higher price usually covers the full lifecycle of the part.

Aftermarket tail lights are cheaper upfront. But the final cost depends heavily on quality and vehicle compatibility. Over time, additional costs can add up as:

- Reinstallation due to poor fitment.

- Purchasing resistors or CANBUS adapters to clear error codes.

- Labor time spent diagnosing flickering or warning lights.

- Replacement after moisture damage or early failure.

Tail Light Replacement Cost Comparison

| Cost Factor | OEM | Aftermarket |

|---|---|---|

| Purchase Price | High | Low |

| Installation | One-time | May repeat |

| Error Code Fixes | None | Possible |

| Moisture Damage Risk | Very low | Brand-dependent |

| Total Cost Predictability | High | Variable |

OEM vs Aftermarket: Who Should Buy What?

Different users can benefit from different types of tail lights:

| User Profile | Recommended Type | Why |

|---|---|---|

| Daily Driver | OEM | OEM tail lights offer reliable fitment and minimal maintenance for everyday use. |

| Long-Term Owner | OEM | Over years of ownership, OEM parts reduce the risk of reinstallation, moisture issues, and electrical faults. |

| Lease Vehicle | OEM | OEM tail lights comply with manufacturer standards and avoid issues during lease return inspections. |

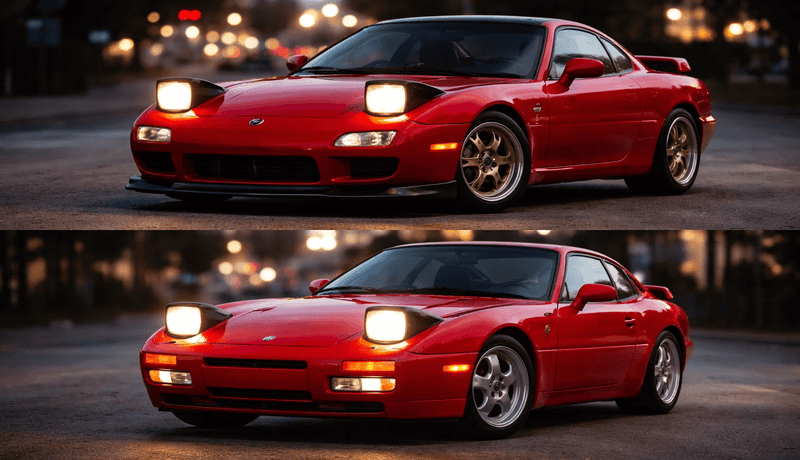

| Custom/Modded Car | Mid/High-Tier Aftermarket | High-quality aftermarket tail lights allow styling or LED upgrades. Maintain acceptable fitment and compatibility. |

How to Choose a Good Aftermarket Tail Light

Choosing quality parts saves money long term. Before purchasing aftermarket tail lights, understand these steps to avoid common fitment, electrical, and durability issues.

1. Confirm Vehicle-Specific Fitment

Avoid “universal” or shared-mold designs. Many low-cost taillights use the same bulb housing for multiple models. It can lead to panel gaps, vibration, or misaligned mounting points. Always verify that the part number is designed specifically for your vehicle’s year and trim.

2. Check CANBUS and Error-Code Compatibility

Modern vehicles monitor lighting circuits. Incompatible taillights can trigger dashboard warnings, flickering, or shut-off protection. Look for units labeled as CANBUS-ready or tested for your platform. Good lights consistently perform in all conditions.

3. Inspect Sealing and Moisture Protection

Poor sealing is a leading cause of aftermarket failure. Weak gaskets or thin plastic housings allow condensation, which leads to corrosion, short circuits, and early LED bulb failure.

Review Materials and Build Quality

Low-grade plastics warp under heat from LEDs or sunlight. It causes lens discoloration and seal breakdown. Higher-quality units use UV-resistant lenses and heat-stable housings to maintain clarity and structural integrity.

Verify Warranty and Supplier Support

A real manufacturer’s warranty indicates confidence in the product. Brand reputation is crucial when choosing parts. Sellers without clear warranty terms mostly resell generic parts with no quality control. Always browse customer reviews and ratings before purchase.

Conclusion

The choice between OEM and aftermarket tail lights depends on cost, reliability, and compatibility. OEM tail lights fit perfectly and integrate fully. But they cost more upfront with lower long-term risk. Aftermarket tail lights are cheaper and can work well if selected carefully.

But they mostly need resistors or better sealing. Considering vehicle sensitivity, usage, supplier quality, and total ownership cost leads to a smart decision.

Choose the Right Tail Lights Without Any Risk

At Car Light Vision, we supply businesses with verified OEM parts and rigorously tested aftermarket taillights that meet fitment, electronic, and regulatory standards. Request a quote today or download our catalog to access reliable tail light solutions built for performance, compliance, and long-term value.

FAQs

Q1: Are OEM taillights better than aftermarket?

OEM tail lights fit perfectly and are compatible. They have the lowest risk of leaks or error codes. Aftermarket tail lights can work well, but quality varies by brand and design. The safest choice depends on vehicle type, usage, and supplier quality.

Q2: Do aftermarket LED taillights need resistors?

Many aftermarket LED taillights need resistors because LEDs draw less power than halogen bulbs. This can trigger warning lights or hyper-flashing unless the assembly is CANBUS-compatible. Some premium aftermarket designs include built-in load control.

Q3: Can aftermarket tail lights cause inspection failure?

Yes, if they are not DOT or E-mark compliant. Also, if brightness, color, or reflectors don’t meet legal standards. Poor fitment or exposed wiring can also cause failures. Always verify regulatory approval before buying.

Q4: Can I replace just the bulbs instead of the full assembly?

You can replace bulbs if the housing is sealed and undamaged. Full assembly replacement is needed when there is cracking, moisture inside, or when LEDs are integrated and non-serviceable.